There are three main techniques used for site stabilisation; Dynamic Compaction, Vibro Compaction and Vibro Replacement.

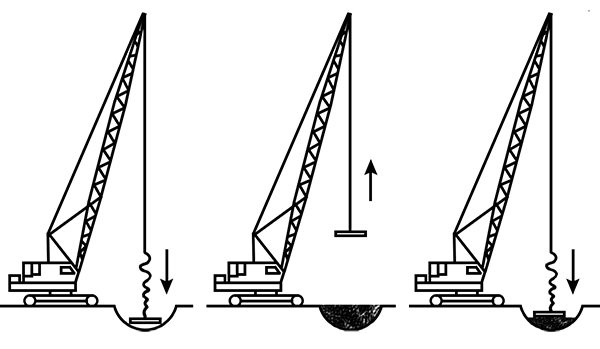

Dynamic Compaction

Using a heavy steel / concrete tamper that can weigh up to 20 tonnes, the ground is subjected to repeated surface tamping with a drop in free fall from heights of up to 25m. A grid is set up for the tamper to be dropped a set number of times over the site to form a pass, two to five passes are required on a site. Imprints from the tamper are in-filled with a granular material after each pass.

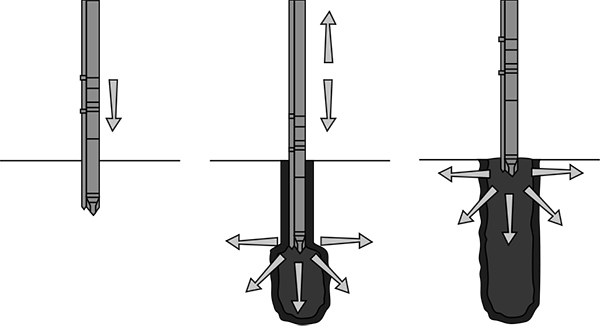

Vibro Compaction

In weak granular soils, water jetting can be used to remove soft materials and stabilises the hole. The stone backfill descends to the bottom of the vibrator and compacted / interlocked with the surrounding soil.

Vibro Replacement

Stone columns are constructed to allow the vibrator to penetrate to design depth, this leaves a cavity which is then filled with hard inert stone. Each stone column is compacted in stages to create interaction between the stone columns and surrounding soils.