Driven piles are installed using a drop hammer rig or vibro rig. Driven piles are cost effective and accommodate various soil conditions, the standard sizes are 100mm, 150mm, 220mm, 300mm and 350mm. The benefits to driven piles are they maintain shape during installation and aren’t susceptible to damage from the installation of other piles.

Techniques

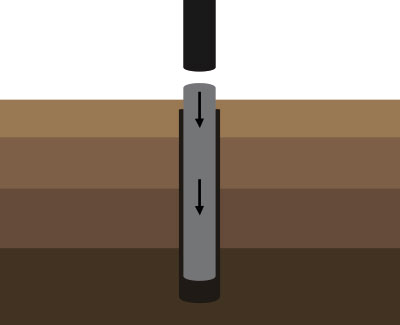

Steel-Cased Driven Piles

- Steel casings are driven into ground to depths designed by engineer.

- The steel casings are then filled with concrete and reinforcement is placed to engineers specifications.

Steel Sheet Driven

- Ideal for retaining earth prior to excavations.

- Steel sheets are driven to the required depth, theses can be removed after construction if required.

Precast

- A precast concrete pile is driven into the ground.

Driven Cast In-situ

- A steel casing is driven into the ground with an attached shoe.

- Once at the required depth, the ground beneath the weight has compacted. The weight is withdrawn ready for the insertion steel reinforcement.

- The concrete is placed into the steel casing.

- A rebar is inserted into the concrete for added reinforcement and concrete is left to set.